|

Restock PTY LTD |

|---|

The terms biodegradable, degradable and compostable are no doubt becoming a frequent occurrence in your daily lives as waste management evolves. Whether it’s items on a supermarket shelf, plastic bottles from your work vending machine or the cutlery you’re using from the takeaway down the road, these terms are important to ensuring our waste is being disposed of properly for the betterment of the environment. What then do these terms mean and how important are they towards Australia’s sustainability?

In basic terms, for something to be biodegradable, it must be able to break down when in the presence of microorganisms, fungi or bacteria like in your compost bin at home. Microorganisms, fungi, or bacteria depend on their enzymes to start the breakdown of substances with the process being carried out in the presence of suitable optimum conditions like temperature, moisture, pH levels and oxygen. It’s important to note that without these optimum conditions, degradation can take longer. For instance, paper should only take 2-5 months to biodegrade but there have been some instances where newspapers in landfills, which generally have poor oxygen and organism levels, have been found to take years to breakdown with some still being readable.

Generally, naturally biodegradable materials include paper, plants, animal waste, human waste, food waste as well as things like wool, cotton, oils, leather, and metals. There are also synthetically made materials that under the right conditions in waste management facilities can biodegrade. Biodegradable plastics and foams are now becoming widely used to make things like plastic straws, plastic plates, plastic, or foam cups and plastic cutlery with a range of these products available at Restock. Detergents and washing liquids are also taking the biodegradable route to help protect our waterways and environment with Restock’s own brand of chemicals, Eurosan being an industry leader.

In a sense, almost everything is degradable with there being two primary ways for degradation to occur. For something to degrade it must be able to break down either biologically or chemically. Biologically occurring degradation is not the same as biodegradable degradation, which requires the presence of microorganisms, fungi, or bacteria. Instead, conditions of heat, sunlight and/or moisture are all that is required for the breakdown process to succeed. Chemically occurring degradation on the other hand requires the use of a variety of synthetic chemicals/substances that breakdown the chemical structures of degradable waste.

The most common items that experience biological degradation is plastics, glass, rubber and tin or aluminium cans. Plastic for instance can take up to 450 years to completely breakdown which creates a secondary problem in that a slowly degrading piece of plastic creates microplastics which eventually creates nano plastics. Microplastics, fragments of plastics 0.1 μm (micrometre) −5 mm in size, are becoming a considerable issue, especially in waterways and oceans where marine life consume these particles with the results often being fatal due to digestive tracts clogged with indigestible plastic contents. Nano plastics, with dimension of between 0.001–0.1 μm, are of particular concern too as research has shown these particles to have penetrated human cells and even occur in blood results. Due to the harmful nature of plastics waste management is quickly becoming a very important industry to our future not only to remain sustainable or environmentally friendly but to dispose of waste safely. One waste management degradation method that is becoming more common for plastics, as well as rubber is incineration or combustion this not only prevents the chance of micro and nano plastics degrading in the environment but also creates an energy generating source which can be converted into valuable electricity.

Often confused with being biodegradable, compost or compostable items are structurally made of organic matter which can completely breakdown to make nutrient rich soil. Once a particular material has turned into compost, it should have left no toxic residue in the soil.

For something to turn into compost, degradation should occur within 12 weeks (for industrial composting) whereas residential composting in your compost bin at home can take months. The ideal compostable conditions include the right temperature, oxygen, and moisture.

The most common compost materials are organic waste products like food scraps and plant matter. Other more complex materials can also be composted, such as PLA (polylactic acid), a popular biodegradable material for green companies which will only decompose into carbon dioxide and water in a controlled industrial waste management composting environment, not in a typical backyard compost bin.

Our selection of utensils, as well as our fluted burger clams, are all certified to Australian compostable industrial standards.

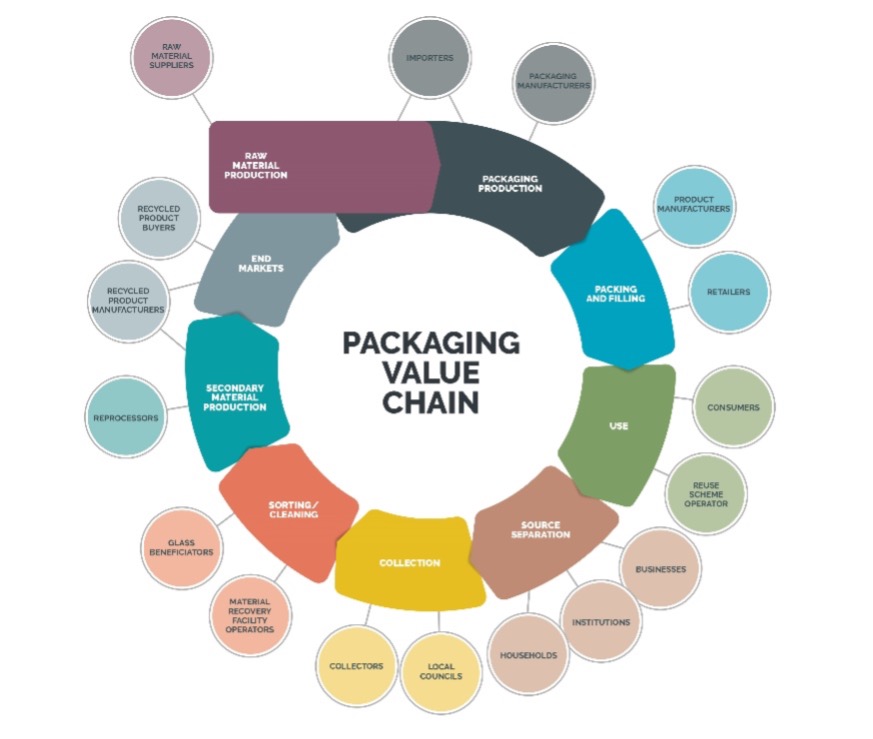

Australia has created an ambitious national packaging target which aims to completely replace the use of plastics with 100% reusable, recyclable or compostable packaging by 2025. For plastics still in circulation after 2025, Australia is seeking a 70% recycling rate, up from 16% in 2019/20. Figure 1 below shows the intricacies of achieving this goal and the various stakeholders that need to work together for these targets to be met.

As of July 2022, Australia will also be phasing out biodegradable plastics as part of a waste management plan. This may seem surprising as it is seen as a great alternative to traditional plastics but the problem lies with the lack of regulations or standards of what ‘biodegradable plastics’ actually mean. Some biodegradable plastics are still in fact made using fossil-fuels but have added chemicals that help them break down quicker into micro and nano-plastics. Other biodegradable plastics are made from plant-based materials but there is no clear research on what the perfect environment is for these items to break down in, meaning some may stay intact for years.

Other targets, as outlined in the National Plastics Plan, that Australian aims to meet are as follows:

(AS4736-2006, AS5810-2010 and EN13432)

packaging (July 2022), and food and beverage containers (December 2022)

Label (December 2023)

Figure 1 – Packaging Value Chain

Source: https://apco.org.au/national-packaging-targets

This is a huge step towards a more sustainable future for Australia and one where biodegradable and compostable products will become everyday items for industrial, retail and household use.

At Restock, we are fully committed to adhering to all new government regulations and initiatives to help better our sustainability nationwide, with environmental and sustainability a key part of our customer value offering.